Using Acid Mine Wastewater to Reduce Radioactivity of Fracking Wastewater

By Dan DeBaunShare

A new study led by scientists from Duke University has revealed that radioactivity of fracking wastewater may be reduced by blending it with wastewater recovered from acid mine drainage. Wastewater from both fracking and acid mine drainage are known to pose a potential health risk both to the environment and to humans. However, laboratory test results from the study, which was published in the peer-reviewed journal Environmental Science & Technology in December 2013, have shown that when wastewater from these two sources are blended in the correct proportions it is possible to bind some of the contaminants found in fracking water into solids that facilitates their removal prior to the water being discharged into rivers.

“This could be an effective way to treat Marcellus Shale hydraulic fracturing wastewater, while providing a beneficial use for acid mine drainage that currently is contaminating waterways in much of the northeastern United States,” said Avner Vengosh, professor of geochemistry and water quality at Duke's Nicholas School of the Environment. “It's a win-win for the industry and the environment.”

The above picture is of an oil and gas wastewater facility. Blending wastewater from fracking operations with wastewater from acid mine drainage could also provide a usable source of recycled water that can be used during hydro-fracking operations, which would in turn reduce the pressure on freshwater resources that are currently being unsustainably utilized and rapidly depleted.

The hydraulic fracturing process involves pumping millions of tons of water into drilled gas wells under high pressure, which forces open fissures in the shale deposits, releasing the natural gas contained within so that it can be extracted. However, some of the water that is pumped into the well returns to the surface together with the natural gas being extracted. This fluid, commonly referred to as 'flowback fluid', typically consists of high concentrations of naturally occurring salts, metals (such as strontium and barium), and radioactive substances such as radium.

A previous study conducted by the Duke research team revealed that the standard methods used to treat fracking wastewater only partially remove these potentially hazardous pollutants from fracking waste, resulting in radioactive wastewater being released into freshwater systems where they tend to accumulate in sediments of rivers and streams near the point of discharge.

Acid mine drainage, which is potentially extremely toxic to fauna and flora as well as humans, seeps out old disused coal mines, contaminating many freshwater systems within the Appalachian Basin, negatively impacting the quality of water in hundreds of rivers and streams throughout West Virginia and Pennsylvania.

As a large portion of Marcellus shale gas exploration is occurring in areas that were historically used to mine coal, experts proposed that acid mine drainage could offer an alternative and more sustainable water source to use in fracking operations and reduce the pressure on limited freshwater sources, which are currently under strain.

In order to test this theory, Vengosh and his fellow researchers blended various mixtures of Marcellus Shale hydro-fracking wastewater together with acid mine drainage – all samples where provided to them by operators drilling for gas in the western Pennsylvania area.

After two days, the researchers assessed the chemical and radiological make-up of 26 of the blended mixtures, using geochemical modeling techniques to simulate both the physical and chemical reactions that took place after the fracking and acid mine drainage waste-waters were blended. The scientists then verified their results with x-ray diffraction and by taking radioactivity measurements from the solids that formed as a result of the mixing.

“Our analysis suggested that several ions, including sulfate, iron, barium and strontium, as well as between 60 and 100 percent of the radium, had precipitated within the first 10 hours into newly formed solids composed mainly of strontium barite,” Vengosh said.

It was now possible to separate the radioactive solids from the fluids so that they could be disposed of at an appropriate hazardous waste disposal site, and with the radioactive material safely removed, the water would pose less of an environmental and health risk if discharged when discharged into waterways. Moreover, because the blending process also removed salts, salinity levels were also reduced, making the wastewater now suitable to be recycled for use in the hydro-fracking process.

“The next step is to test this in the field. While our laboratory tests show that is it technically possible to generate recycled, treated water suitable for hydraulic fracturing, field-scale tests are still necessary to confirm its feasibility under operational conditions,” Vengosh said.

This sounds almost too good to be true - could two wrongs possibly make a right?

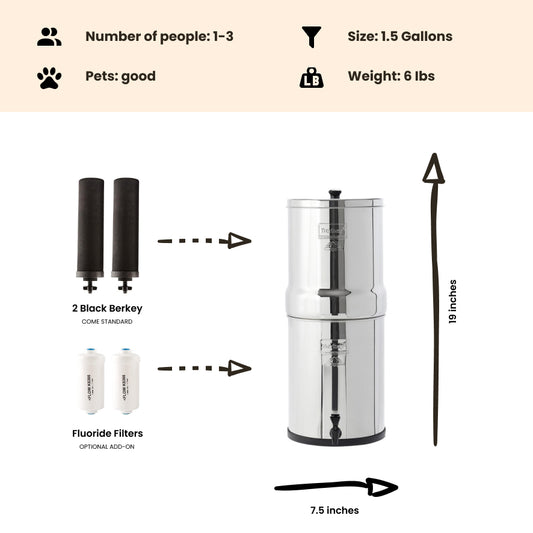

NOTE: While the above research holds some promise for removing radioactive contaminants from the wastewater, it cannot remove pollutants from water that is not returned to the surface – i.e. frac-water full of chemicals and radioactive material that leaches through the ground to contaminate groundwater and drinking water in wells. If your water comes from a source that could be contaminated, rather take the necessary precautions to remove these potentially harmful pollutants by filtering your drinking water with a good quality water filter.

Journal Reference:

"Radium and Barium Removal through Blending Hydraulic Fracturing Fluids with Acid Mine Drainage," Andrew J. Kondash, Nathaniel R. Warner, Ori Lahav, Avner Vengosh. Environmental Science & Technology, Dec. 24, 2013, https://dx.doi.org/10.1021/es403852h

-

Regular price $234.00 USDRegular priceUnit price / per

-

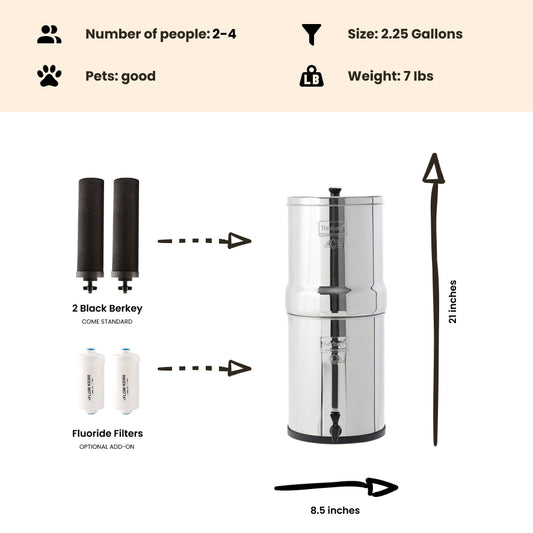

Regular price $327.00 USDRegular priceUnit price / per

-

Regular price From $367.00 USDRegular priceUnit price / per

-

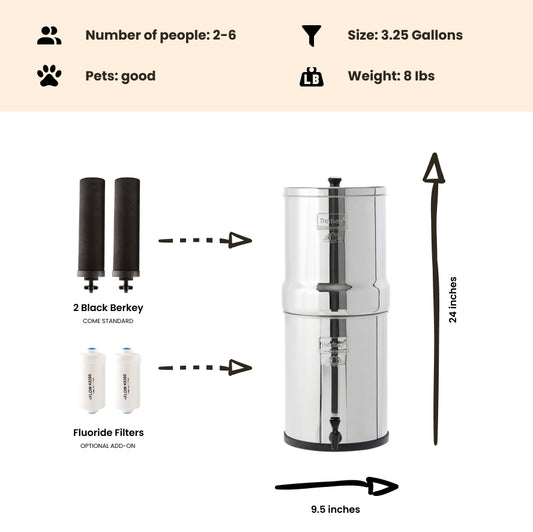

Regular price From $408.00 USDRegular priceUnit price / per

-

Regular price From $451.00 USDRegular priceUnit price / per

-

Regular price From $478.00 USDRegular priceUnit price / per

-

Regular price $332.50 USDRegular priceUnit price / per

$350.00 USDSale price $332.50 USDSale

Dan DeBaun is the owner and operator of Big Berkey Water Filters. Prior to Berkey, Dan was an asset manager for a major telecommunications company. He graduated from Rutgers with an undergraduate degree in industrial engineering, followed by an MBA in finance from Rutgers as well. Dan enjoys biohacking, exercising, meditation, beach life, and spending time with family and friends.

~ The Owner of Big Berkey Water Filters